Powder Coating

Powder Coating

Powder coating is by far the youngest of the surface finishing techniques in common use today. The basis of any good coating is preparation. The vast majority of powder coating failures can be traced to a lack of a suitable preparation. Our five stage cleaning process prepares the products on the most economical way. There after the powdered paint is electrostatically charged and sprayed onto the part and then placed in an oven. The powder particles melt and coalesce to form a continuous film.

Our range of stock colors creates a wide range of possibilities. The choice of colors and finishes is almost limitless and can be ordered on request. Our fully automated plants allows us a great deal of flexibility in the market.

Pickling & Passivation

Stainless steels rely on a very thin surface passive film for their corrosion resistance. It is vital to maintain and preserve the integrity of the passive film. When a Stainless is welded this passive film is damaged and the affected areas require repair by pickling & passivation which is achieved via a dip system. Once this process is complete a constant and sufficient availability of oxygen at the surface of the stainless steel must be achieved for best results.

Powder Coating Disclaimer

We have been running our in-house powder coating plants in excess of 15 years and during this period have gained valuable knowledge and experience with the procedure. The coverage and density of the powder especially on sharp edges has only become a real concern over the last couple of years due to the reduction and or removal of TGIC and Lead from the powder. These components have been reduced/removed due to government regulation worldwide as everyone’s goal is to go green and use more organic substances.

We believe it is our duty and responsibility to inform you our customers of the issues that can arise from choosing the incorrect material and or coating for the corrosion protection of your particular product. As a standard we apply a single coat of powder which is suitable for indoor use only and carries a 24 month warranty.

This warranty covers that the process of pre treatment and cure of powder coated products meets or exceeds the industry standard. Hitech warrants against cracking, peeling or excessive fading due to normal wear and tear, damage caused by mechanical abuse such as scratches, rough handling, installation or vandalism is not covered by this warranty.

For exterior, coastal or harsh environments alternatives must be investigated. Below please find some possible solutions:

• Apply a Zinc based undercoat and then a final coat.

• Zinc Plate products and then apply the final coat.

• Change the base material to a galvanised, 3CR12 or Stainless Steel.

Herewith please find some information with regards to common issues related with Powder Coating as well as the corrosion levels of the country.

Believe it or not the Highveld’s environment is just as corrosive as some coastal areas.

Powder coating is still one of the most cost effective coatings available as well as the most aesthetically pleasing, the key is knowing how corrosive the environment is and ensuring that the correct mix of components is applied.

Electro Chemical Cleaning / Marking

This process cleans and passivates instantly without the need to wait for pickling paste or gel to react and without leaving “haloes”. It cleans by means of an instantaneous electrolyte reaction with the chemical agent, the result is excellent quality cleaning and passivation of welds on Stainless Steel items which have been MIG or TIG welded.

The Marking System allows any logo or graphics to be instantaneously and permanently etched onto Stainless Steel with a maximum height of 70mm and any length.

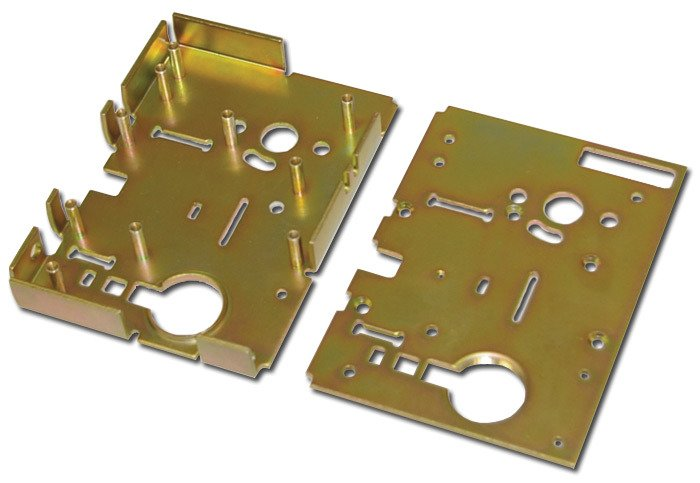

Electro Plating

One of the latest advancements of Hitech is an automated Electro Plating Plants. Electroplating involves the coating of an electrically conductive object with a layer of zinc using electrical current. Usually, the process is used to deposit an adherent surface layer of a metal having some desired property (e.g., abrasion and wear resistance, corrosion protection, lubricity, improvement of aesthetic qualities, etc.) onto a substrate lacking that property.

The product finishes are as follows:

- Yellow Passivated

- Blue Passivated

- Yellow Passivated with Superseal

- Blue Passivated with Superseal

- Plating with no Passivation – preparation for Powdercoating