Machining Services

In the Machining area of our production process, we take care of all the Turning, Milling and Bush & Stud Inserting requirements.

We have a traditional lathe, 3 CNC Turning and Machining centres, and various other conventional machines. To view the various services we offer, please browse through the pages in the drop down menu under Machining Services.

Milling

The milling process is a machine tool that rotates a circular tool with numerous cutting edges arranged symmetrically about its axis, called a milling cutter. The metal work piece is usually held in a vice clamped to a table that can move in three perpendicular directions. Cutters of many shapes and sizes are available for a wide variety of milling operations. Milling machines cut flat surfaces, grooves, shoulders, inclined surfaces, dovetails, and T-slots. Various form-tooth cutters are used for cutting concave forms and convex grooves, for rounding corners, and for cutting gear teeth.

We have various conventional as well as 3 CNC machining centres with combined maximum working dimensions as follows, X-1020mm, Y-550mm and Z-540mm.

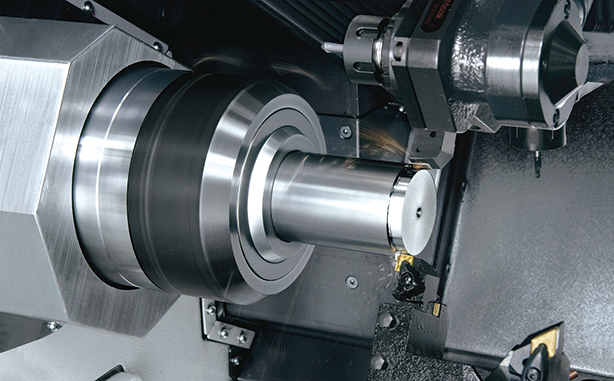

Turning

Turning is the process whereby a centre lathe is used to produce “solids of revolution”. It can be done manually, in a traditional form of lathe, which frequently requires continuous supervision by the operator, or by using a computer controlled and automated lathe which does not. This type of machine tool is referred to as having computer numerical control, better known as CNC.

We have various conventional as well as 3 CNC Turning centres with combined maximum working dimensions as follows, 280mm diameter and 550mm long.

Stud & Bush Inserting

Fasteners for sheet metal provide deep tapped female threads(ARB’s, Minarb’s, and Self Clinching Stand off’s) or Self Clinching studs for use in conjunction with thin sheet metals. Once installed, they are permanently attached to the mating material, allowing the associated nut or bolt to be removed in service without the risk of the fastener becoming dislodged. Self-clinching fasteners are easily installed using traditional installation equipment, such as a Haeger Presses. Our factory is complimented by 2 off Haeger 618 Modular Autofeed Systems with 6 tons of ram force and a 457mm throat depth. We tackle the larger jobs with the Haeger 824 Plus with 8 tons of ram force and a 610mm throat depth.